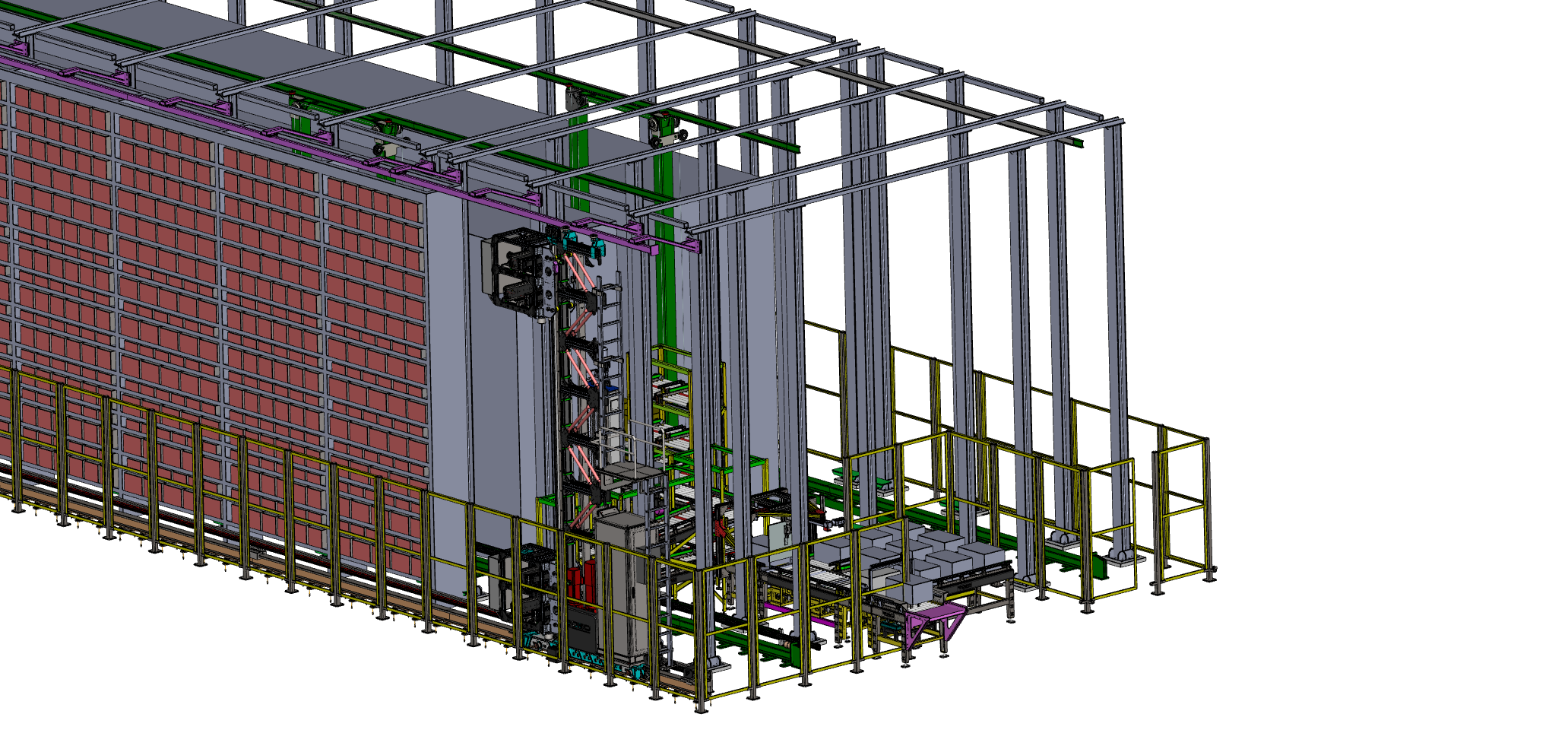

Mini-Load AS/RS Part Storage System

Prosimtech Engineering has developed a Mini-Load AS/RS (Automated Storage and Retrieval System) solution that ensures precise, secure, and fully automated management of specialized parts and components used in production facilities.

This system provides a high-tech hardware and control infrastructure for fast, accurate, and traceable retrieval, storage, and return of small-volume materials.

System Description

The Mini-Load AS/RS system is a warehouse automation solution designed for the precise, automated, and high-speed handling of materials.

Key components include:

-

Storage Racks: Custom steel structures up to 7 meters in height

-

Robot Crane (Stacker Crane): Automated carrier that picks and places materials on the racks

-

P&D (Pick-up & Deposit) Stations: Input/output points where materials are delivered to or retrieved from the system

-

Control System: Prosimtech’s WMS-based automation infrastructure manages the robot crane, conveyors, and sensor network

This configuration enables a fully unmanned, low-error, and highly accurate storage solution.

Mini-Load AS/RS Features

-

Material Types: Boxes of 300×140×400 mm, 300×280×400 mm, 400×280×600 mm

-

Rack Dimensions: 1000×6500×45700 mm

-

Warehouse Height: 7 meters

-

Capacity: 2,000+ storage locations

-

Conveying System: Servo-controlled mini crane + static P&D stations

-

Station Type: Static (fixed rack-connected) P&D structure

-

Control Infrastructure: Siemens S7-1500 PLC + Profinet

-

Software Infrastructure: Prosimtech WMS (Warehouse Management System)

-

Energy System: Regenerative servo-driven motors

Operating Principle

-

The operator places or retrieves material at the static P&D station.

-

The robot crane detects the box via sensors and stores it on the appropriate rack.

-

The system automatically records the storage address of each item.

-

Upon request, the robot crane retrieves the box and delivers it to the designated P&D station.

-

The operator picks the part, and the box is automatically returned to its rack.

This cycle is completed in seconds, providing high-speed operation with minimal errors.

System Advantages

-

High accuracy in small-part management

-

100% traceability and digital inventory tracking

-

Fully automated flow following FIFO principles

-

Saves labor and time

-

Secure storage of critical parts

-

Operator-free, ergonomic, and safe operation

-

Low maintenance and high system continuity

The Mini-Load AS/RS system is ideal for production and logistics environments where secure storage of specialized parts is critical. It efficiently utilizes warehouse heights of up to 7 meters, maximizing storage space and operational efficiency.

Prosimtech Engineering Contribution

Prosimtech Engineering developed all mechanical, electrical, and software components in-house, including:

-

3D mechanical and rack design

-

Servo-controlled mini crane manufacturing

-

P&D station integration

-

WMS and automation synchronization

-

Testing, commissioning, and operator training

The project was implemented with a fully domestic design and control infrastructure, providing a scalable automated storage solution suitable for production lines and warehouse operations across different industries.

- Built-in Oven Production Montage Line

- Dishwasher Inner Casing Storage Line

- Mini-Load AS/RS Part Storage System

- BAM Battery 27K Assembly Line

- Oven Lift

- Crapline KLT Box Stock Line

- Tire Buffer Conveyor and Storage Project

- Door Transport Project

- Skid Charger Conveyor Project

- Mezannin Buffer Conveyor Project

- Truck Welding Line Conveyor System

- Built-in Oven Production Montage Line

- Dishwasher Inner Casing Storage Line

- Mini-Load AS/RS Part Storage System

- BAM Battery 27K Assembly Line

- Oven Lift

- Crapline KLT Box Stock Line

- BEV Battery

- External Conveyor Project

- AGV

- V710 Conveyor Project

- Welding Line

- J74 Volkswagen Welding Line

- Transformer Transport Finite Element Analysis FEA