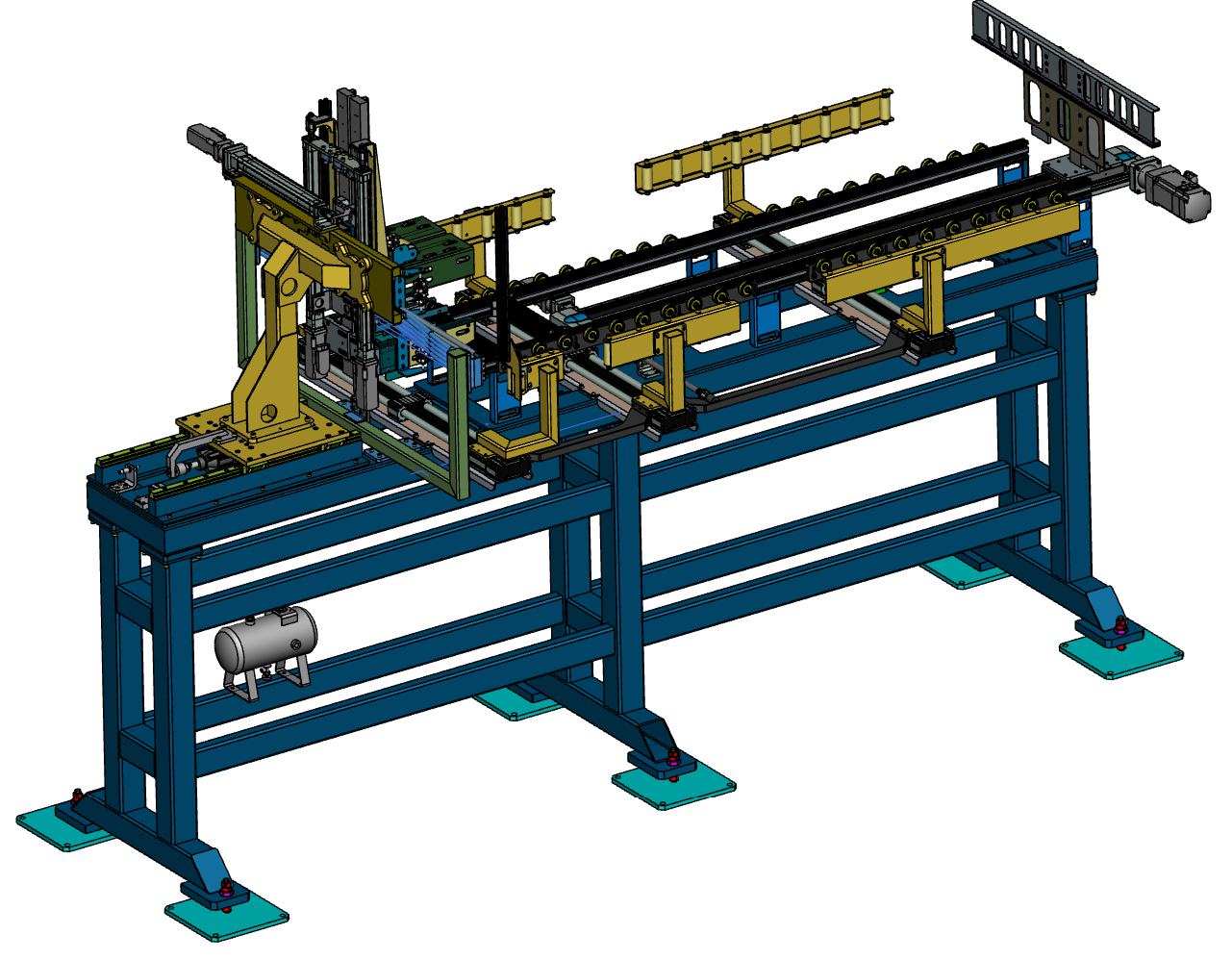

Cardboard Bottom Skirt Opening Machine

Prosimtech Engineering provides speed, precision, and full automation in packaging processes with the Cardboard Bottom Skirt Opening Machine, developed for Arçelik Eskişehir Refrigerator Plant.

The system fully automates the process of opening and forming cardboard bottom skirts used in refrigerator packaging.

Project Description

The Cardboard Bottom Skirt Opening Machine converts the manual bottom skirt preparation process into a servo-driven automated system.

Integrated with the conveyor line, the machine receives, opens, shapes, and prepares the cardboard skirts for the next stage of the line.

Its X–Y–Z servo-axis structure automatically adjusts positioning according to the size and thickness of the cardboard.

The PLC-controlled system manages all movements through predefined automation scenarios, with the operator only selecting the product to safely operate the line.

Technical Specifications

-

Axis System: X–Y–Z servo-controlled structure

-

Control Infrastructure: Siemens S7-1200 PLC

-

Communication: Ethernet/IP protocol

-

HMI Control Panel: Automatic / Manual / Test mode transitions

-

Pneumatic System: SMC valve island with regulation equipment

-

Bearings and Slides: THK linear system, SKF bearing group

-

Machine Body: Steel construction with industrial epoxy coating

-

Power Supply: 380V AC, 50Hz

-

Compressed Air: 6 bar operating pressure

-

Safety Equipment: Light barriers, safety sensors, and locked access panels

The system complies with CE, ISO 12100, and EN 13849-1 safety standards.

Automation and Software

-

Servo motors automatically update position information based on cardboard type.

-

The PLC system generates motion profiles according to parameters entered via the HMI.

-

All axis movements are synchronized via Ethernet/IP protocol.

Operator panel features include:

-

Product model selection

-

Servo position reset

-

Error analysis and fault history

-

Manual test commands

The system is integrated with the production data infrastructure, sending cycle counts and fault data per productdirectly to Arçelik’s traceability system.

Key Benefits

-

Eliminates manual labor requirements

-

Increases production speed by 30%

-

Zero adjustment time during model changes

-

Prevents cardboard deformation

-

Ensures operator safety and ergonomics

-

High repeatability with servo positioning

-

Minimal maintenance requirements

Prosimtech Engineering Contribution

Prosimtech Engineering completed all mechanical and automation infrastructure of this project with its in-house engineering team.

Scope of work included:

-

3D mechanical design

-

Servo system configuration

-

PLC & HMI software development

-

Electrical panel design and on-site installation

-

Operator training and commissioning

All stages were delivered turnkey, ensuring full operational readiness.

- Built-in Oven Production Montage Line

- Dishwasher Inner Casing Storage Line

- Cardboard Bottom Skirt Opening Machine

- Mini-Load AS/RS Part Storage System

- Parallel Skid Conveyor Project

- BAM Battery 27K Assembly Line

- Tire Buffer Conveyor and Storage Project

- Door Transport Project

- Skid Charger Conveyor Project

- Mezannin Buffer Conveyor Project

- Truck Welding Line Conveyor System

- Built-in Oven Production Montage Line

- Dishwasher Inner Casing Storage Line

- Cardboard Bottom Skirt Opening Machine

- Mini-Load AS/RS Part Storage System

- Parallel Skid Conveyor Project

- BAM Battery 27K Assembly Line

- Back Cardboard Gluing

- Riveting Burner Box

- MKYS Engine Complexity Management System

- Oven Lift

- Crapline KLT Box Stock Line

- BEV Battery

- External Conveyor Project

- AGV

- V710 Conveyor Project

- Welding Line

- J74 Volkswagen Welding Line

- Mortar Shell Filling Line

- Transformer Transport Finite Element Analysis FEA