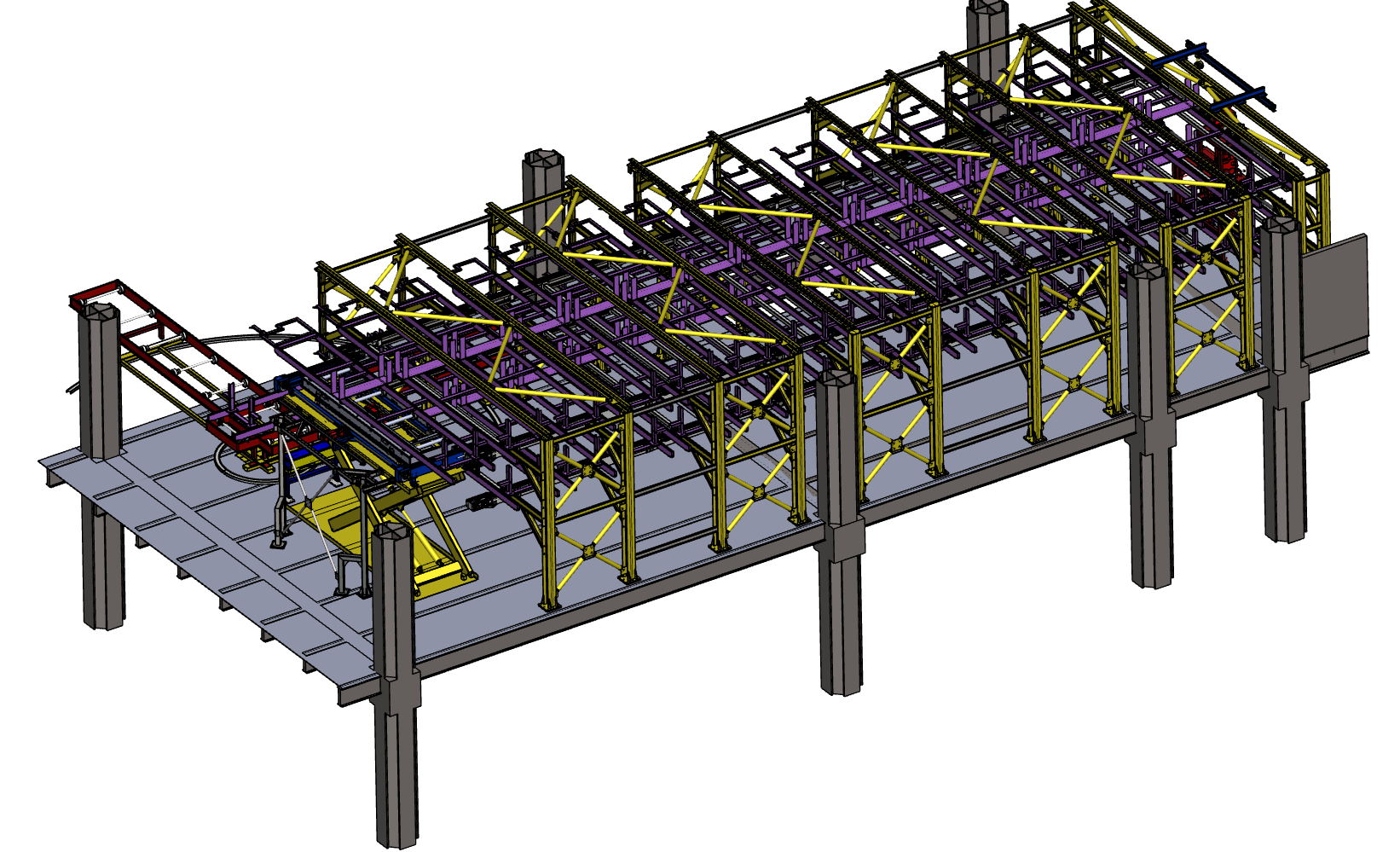

Skid Charger Conveyor Project

Prosimtech Engineering offers modern industrial solutions with its Skid Charger System, developed to increase efficiency in automotive production lines.

This system automatically stacks, stores, and safely transfers skid (carrier pallet) units along production lines according to line sequence.

Purpose of the Skid Charger System

Skid charger systems are designed to:

-

Increase space efficiency

-

Organize material flow

-

Ensure operational continuity

Its fully automated structure allows entry and exit of skids without human intervention, improving efficiency and maximizing workplace safety.

Technical Specifications and System Components

-

Multi-level skid storage system: Maximum capacity in minimum space

-

FIFO principle: Error-free and sequential skid transfer

-

Integrated lift and conveyor systems: Fast vertical and horizontal transportation

-

Sensor-based automation: Complete position tracking

-

Galvanized steel construction: High durability and long lifespan

-

Anti-static, non-slip belt systems: Safe transportation environment

-

Modular design: Easy integration with different production lines

Advantages of the Skid Charger System

-

Up to 40% more efficient use of space

-

Continuous production flow with minimal line stoppage

-

Automatic sequencing eliminates operator errors

-

High safety standards with ISG-compliant design

-

Low maintenance cost and long service life

Project Implementation

The Skid Charger System developed by Prosimtech Engineering has been successfully implemented at Ford Otosan production facilities.

Project scope included:

-

Automatic loading and unloading of skids

-

Full control of FIFO flow

-

Digitalization of production line logistics

As a result, the system provides a safe, fast, and sustainable production process, setting a benchmark for automotive manufacturing.

Why Prosimtech Engineering?

-

Expert engineering team specialized in industrial automation and conveyor systems

-

Capability to develop custom solutions for automotive production lines

-

Locally engineered systems meeting high-quality standards

- Tire Buffer Conveyor and Storage Project

- Door Transport Project

- Skid Charger Conveyor Project

- Mezannin Buffer Conveyor Project

- Truck Welding Line Conveyor System

- Built-in Oven Production Montage Line

- Tire Buffer Conveyor and Storage Project

- Door Transport Project

- Skid Charger Conveyor Project

- Mezannin Buffer Conveyor Project

- Truck Welding Line Conveyor System

- Built-in Oven Production Montage Line

- Dishwasher Inner Casing Storage Line

- Mini-Load AS/RS Part Storage System

- BAM Battery 27K Assembly Line

- Oven Lift

- Crapline KLT Box Stock Line

- BEV Battery

- External Conveyor Project

- AGV

- V710 Conveyor Project

- Welding Line

- J74 Volkswagen Welding Line

- Transformer Transport Finite Element Analysis FEA