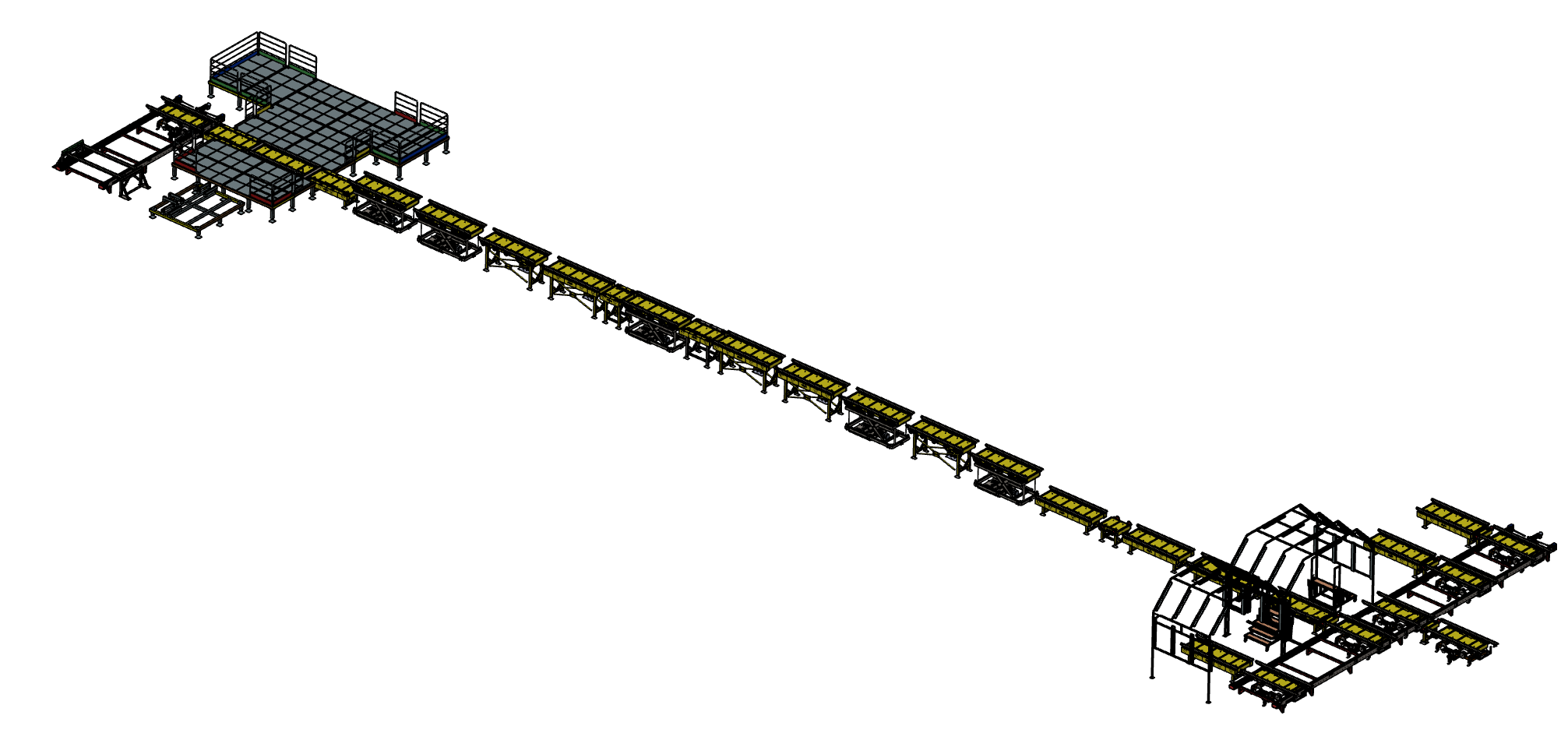

Truck Welding Line Conveyor System

Prosimtech Engineering ensures maximum efficiency, precision, and safety in production processes with its Truck Welding Line Conveyor Systems, developed for heavy commercial vehicle manufacturing lines.

The system provides a fully integrated automation infrastructure with conveyor lines, robotic welding stations, gripper systems, and custom fixture solutions.

System Description

This system is a fully automated welding line used in truck cabin and chassis assembly processes.

Key components of the line include:

-

Chain-driven transfer conveyors

-

Height-adjustable platforms and intermediate lift units

-

Fixed and movable fixtures for welding stations

-

Robotic gripper systems for part transfer

-

Operator access areas and maintenance platforms

This setup ensures fully synchronized material flow on the production line while maintaining a high level of safety.

Technical Specifications

-

Heavy load capacity: Designed for truck chassis and cabin components

-

Precise positioning: Servo motor-controlled transfer units

-

Robotic welding integration: Synchronized operation with MIG/MAG robotic arms

-

Automatic stop and control system: PLC-based synchronization and safety monitoring

-

Modular construction: Facilitates maintenance and rapid commissioning

-

High-strength materials: 4140-grade gears, galvanized steel structure

Key Benefits

-

Up to 30% increase in production speed

-

Fully synchronized material flow

-

Transfer system compatible with robots and fixtures

-

Low maintenance cost with high safety standards

-

Energy-efficient drive technologies

Application Areas

-

Truck and heavy-duty vehicle cabin production lines

-

Chassis welding and assembly lines

-

Automotive body manufacturing stations

-

High-tonnage part handling systems

Prosimtech Engineering Assurance

With expertise in robotic welding systems, custom fixture design, and conveyor integration solutions, Prosimtech Engineering makes truck production lines fully automated and highly efficient.

Each project is delivered turnkey, including:

-

3D design

-

Analysis and simulation

-

On-site assembly

- Skid Charger Conveyor Project

- Mezannin Buffer Conveyor Project

- Truck Welding Line Conveyor System

- Built-in Oven Production Montage Line

- Dishwasher Inner Casing Storage Line

- Mini-Load AS/RS Part Storage System

- Tire Buffer Conveyor and Storage Project

- Door Transport Project

- Skid Charger Conveyor Project

- Mezannin Buffer Conveyor Project

- Truck Welding Line Conveyor System

- Built-in Oven Production Montage Line

- Dishwasher Inner Casing Storage Line

- Mini-Load AS/RS Part Storage System

- BAM Battery 27K Assembly Line

- Oven Lift

- Crapline KLT Box Stock Line

- BEV Battery

- External Conveyor Project

- AGV

- V710 Conveyor Project

- Welding Line

- J74 Volkswagen Welding Line

- Transformer Transport Finite Element Analysis FEA